Industrial Films and Adhesives

Application Overview

In a world that’s constantly innovating and expanding, industrial films and adhesives have come to play a pivotal role. These essential products find applications in numerous sectors, from automotive to construction, electronics to packaging, healthcare, and beyond.

Innovations in polymer and plastics technology have led to the development of films with specific characteristics to suit unique industrial requirements, such as anti-static films for electronics, UV-resistant films for outdoor applications, and breathable films for healthcare products.

They offer an array of properties such as high-tensile strength, durability, and resistance to abrasion, chemicals, and temperature extremes. With such characteristics, these films are ideally suited to safeguard and enhance products, providing weatherproofing, insulation, and more.

Industrial adhesives, meanwhile, serve as the backbone of assembly processes in many industries. These substances, whether water-based, solvent-based, hot melt, or reactive, are used to bond materials together. Their high-strength, versatile, and durable bonding properties have made them a preferred choice over traditional fastening methods like welding, screws, or bolts.

Advanced adhesive technologies have led to the creation of products that can bond dissimilar materials, withstand severe environmental conditions, and provide resistance to chemicals and corrosion. Additionally, these adhesives are used to enhance aesthetic appeal by facilitating seamless and clean joins.

At Polymer Films, we understand that our customers’ needs are constantly evolving. To meet these dynamic requirements, we offer a broad range of high-quality industrial films and adhesives. Our commitment to research and development ensures we stay at the forefront of technology, providing innovative and efficient solutions for every industrial challenge.

Products Used:

Product Examples

Acoustics

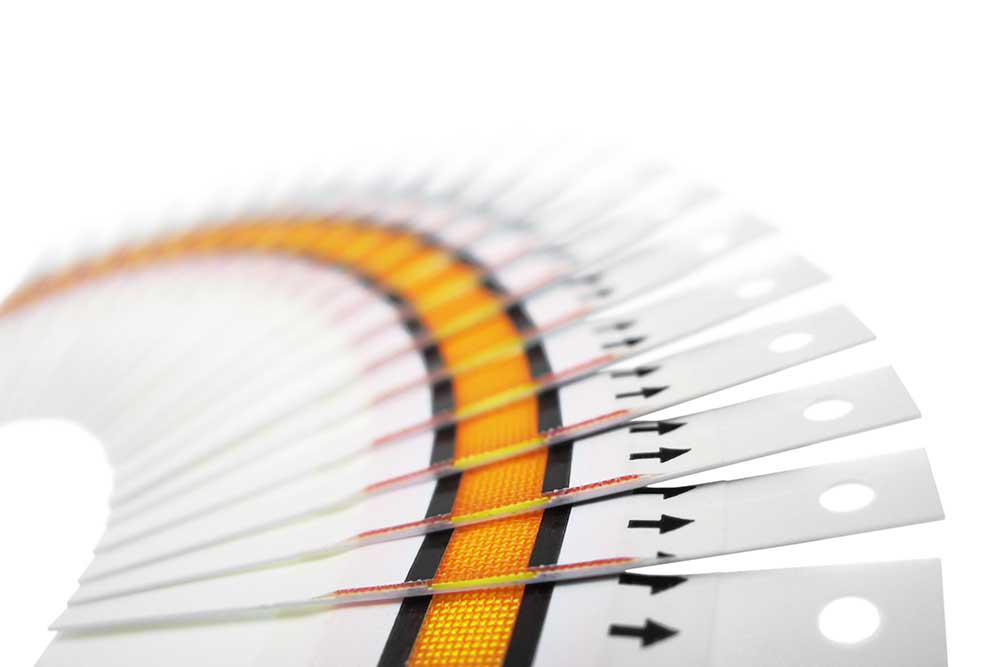

Wiring

Solar

Satellite

Cryogenics

Sound Improvement

The manufacture of high end speakers and sound systems utilize fluoropolymers to assist in better sound and clarity when bonded to other metallized materials.

Spark Resistant

Fluoropolymer films are used in the construction of wiring harnesses due to their ability to suppress flames, protect the wires, and their lightweight.

High Heat Resistance

This film is able to withstand extreme temps when exposed to high heat and super cold conditions. Made of Polyimide film material.

High Heat Resistance

This film is able to withstand extreme temps when exposed to high heat and super cold conditions.

Superior to cold temps

This material is excellent for cryogenic applications from seals, to gaskets to linings for applications that meet the cryogenic temps.

Core

FEP

Clear - A and/or C - .0005" to .0015"

Core

FEP, PFA, Tefzel

Untreated - .0005" to .002"

Core

Polyimide film

.002" - .020"

Core

Tefzel (ETFE)

untreated, .002" - .020"