In-Mold Decorating / In-Mold Electronics

Application Overview

In-mold decorating and in-mold electronics represent a growing field where plastic films play a vital role. These processes involve the integration of graphics or electronics during the molding process, which results in durable and cost-effective components with superior aesthetics or functionality. The choice of plastic films in these applications influences the success of the molding, adhesion, and longevity of the final product.

Products Used:

Material Solutions

Acrylic films for high clarity and scratch resistance

PET films for excellent chemical and dimensional stability

PPG TESLIN® synthetic material for high print quality

Synthetic films for high flexibility and durability

Specialty hard-coated films for in-mold electronics

Product Examples

Automotive Control Panel

Household Appliance Interface

Smart Device Case

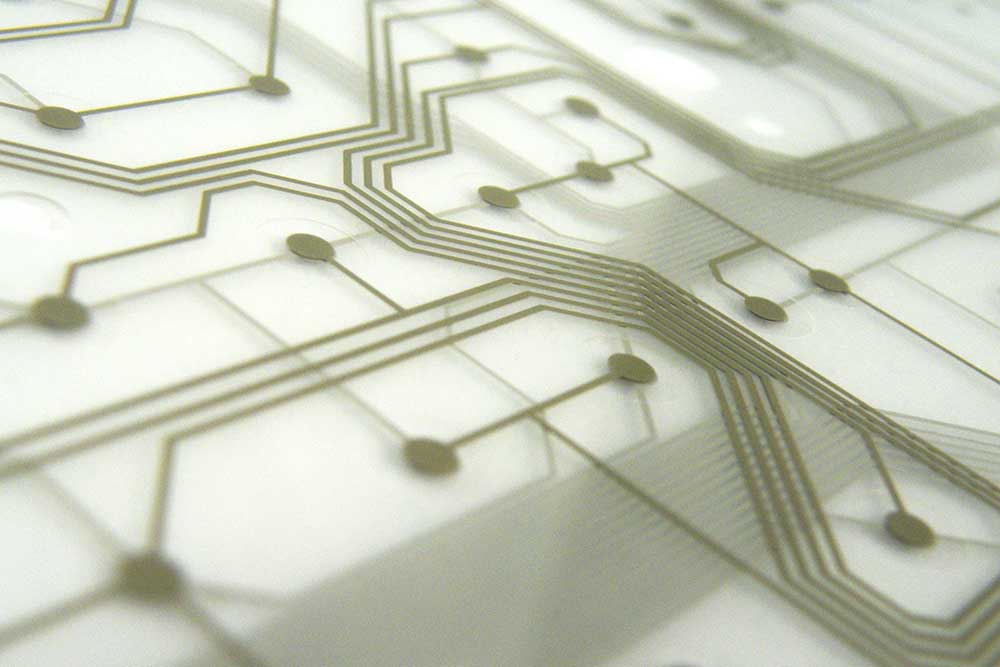

Flexible Circuit

Enhanced Aesthetics and Functionality

Using in-mold decorating and in-mold electronics, automotive control panels can be produced with integrated touch controls, improving aesthetics and user experience.

Robust and Functional

The use of our specialty films in household appliances results in highly durable interfaces that are resistant to wear and tear.

Stylish and Durable

Our materials are used in creating smart device cases with integrated graphics that are scratch-resistant and visually appealing.

Light and Robust

Our synthetic films are perfect for creating light and robust flexible circuits used in various electronic devices.

Core

LEXAN™ (Various textures and finishes)

PC - .007 to .030 - clear

LEXAN™ 6060

PC - .007 to .030 - clear

LEXAN™ HP92x

PC - .007 to .030 - clear

Core

LEXAN™ HP or OQ

PC - gloss/gloss - .007 to .030

Core

Kapton or Apical

Polyimide film - amber

Application Details

The In-Mold Process

In the in-mold process, a plastic film with the desired graphics or circuitry is placed in the mold. The material is then injected into the mold, adhering to the film and creating a one-piece decorated or functional component. The choice of plastic film plays a crucial role in the successful execution of the in-mold process and the performance of the final product.

Future of In-Mold Applications

The in-mold decorating and in-mold electronics market is set to experience significant growth in the coming years. This is driven by the demand for enhanced aesthetics, reduced production costs, and the integration of electronics into structural components. As we move towards a more connected and aesthetically pleasing world, the role of plastic films in these applications is bound to become more important.