Polyethylene Terephthalate (PET) film is one of the most versatile plastic films used across industries today. Because of its exceptional strength, clarity and stability, PET film is the foundation for products in packaging, electrical insulation, and industrial applications.

As a trusted plastic film distributor, PolymerFilms provides high-quality PET film solutions from world-class producers like Mylar Specialty Films, the makers of Mylar® and Melinex®. With over 75 years of distribution expertise, we combine technical knowledge, responsive service and advanced converting capabilities to deliver tailored material solutions for OEMs and manufacturers.

Mechanical, Thermal & Chemical Resistance Properties of PET Film

PET film is valued for its balance of mechanical toughness and dimensional stability. Meaning it resists tearing, puncturing and deformation making it an excellent choice for protective and high-performance applications.

Thermally, PET maintains its strength and clarity across a wide temperature range. Under heat, its dimensional stability allows it to perform consistently in high-speed converting, laminating and electrical insulation processes.

Chemically, PET film offers strong resistance to water, oils and many solvents. This durability ensures long-term reliability in harsh or irregular environments.

With all of these benefits, PET film is also a more sustainable option than many alternatives. It takes less energy to produce and generates fewer greenhouse gases than other common packaging plastics.

PET Film Applications Across Industries

Because of its versatility, PET film plays a key role in a variety of markets:

- Food & Beverage: PET’s clarity, strength and barrier performance make it a top choice for food, beverage and consumer goods packaging. It keeps products fresh and visually appealing while resisting punctures and contamination.

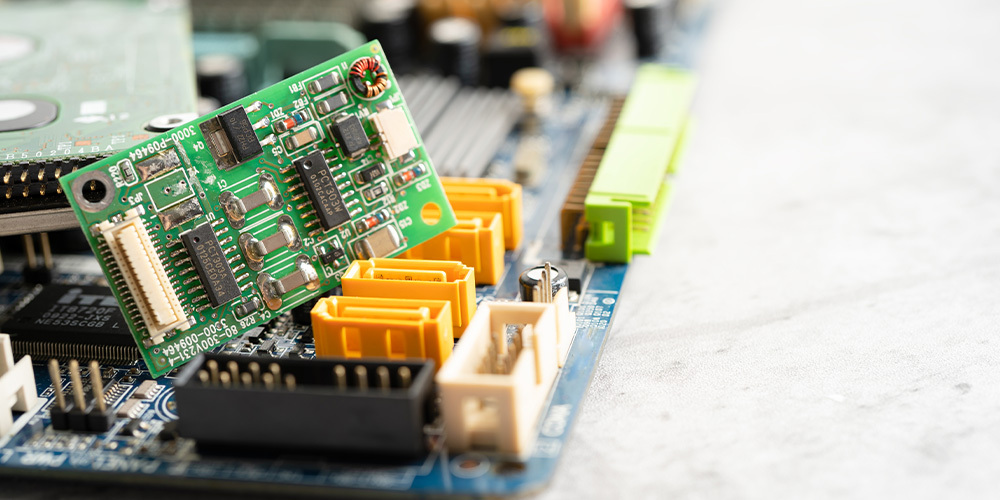

- Electronics: Within electronic systems, PET film is used in flexible circuits, insulation laminates and sensor components where precisions and dielectric strength are critical.

- Insulation and Industrial Applications: PET serves as a durable barrier in composites, vapor seals and power insulation systems while standing up to mechanical and chemical stress in demanding industrial environments.

As a full-service distributor, PolymerFilms supplies PET film for specialized applications. Contact our team to discuss your specific plastic film needs.

PET Film Grades and Characteristics

Different manufacturing processes give PET film its unique grades. Each process is tailored for specific performance needs:

- Uniaxially Oriented PET (U-PET): Stretched in one direction, offering high tensile strength and optical clarity.

- Biaxially Oriented PET (BOPET): Stretched in both directions for superior dimensional stability, tensile strength, and barrier protection that’s ideal for flexible packaging and insulation.

- Metallized PET Film: Aluminum-coated for enhanced barrier protection against moisture, oxygen, and light. This version is often used in food packaging and reflective insulation.

- Specialty PET Films: Options include anti-static, coated, or insulation-optimized grades for advanced applications.

PET film combines performance, durability, and versatility. Understanding its properties and grades helps engineers and product designers choose the best option for each application. Through our extensive inventory and converting network, we supply multiple grades all customized to your project’s performance and form-factor requirements.

Why Partner with PolymerFilms

When you partner with PolymerFilms, you have access to a nationwide distribution network that focuses on quality and customer success. With full film converting capabilities and technical expertise, we are your trusted partner for film solutions.

Contact PolymerFilms today to discuss your next project and discover how our products can support your performance and production goals.

Recent Posts