There are many plastic films that offer strength and rigidity. There are also some that offer resistance to chemicals and/or extreme temperatures. Ultem film provides all of these qualities and more in one powerful plastic film option.

Ultem film is incredibly popular in industrial facilities due to its high quality. If you’re looking for a strong, temperature-resistant film for any applications that support your commercial or industrial operations, here are some things to know about Ultem film.

Attributes of Ultem Film

Ultem film is made using PEI Polyetherimide plastic resins. The plastic film exhibits a wide array of properties that are beneficial in many industrial and commercial use cases. Some qualities that often set it apart from other plastic films include its temperature stability, strength and rigidity, and chemical resistance. Here’s a closer look at these particular attributes:

High strength and rigidity are some of the most notable qualities of Ultem film. It is generally able to stand up against impact force, puncture, and daily wear and tear. Although Ultem is fairly rigid in its thicker plastic form, the film is thin enough to be a bit flexible, allowing it to be used in various containers or membranes.

Ultem film is also fairly chemical resistant. This allows it to maintain its physical properties even when exposed to solvents or cleaning solutions. This is often a useful property in industrial and B2B sectors.

Visually, Ultem film comes in a variety of colors and thicknesses. It can also be fabricated and machined fairly easily. This allows it to work well in applications that require custom specifications. These often include containers like pouches, compartments, and pockets.

Though all of the above qualities are certainly beneficial for many users, the properties that truly set Ultem film apart from other plastics are its temperature stability and flame resistance. Ultem is technically a thermoplastic, meaning it can be shaped when exposed to high heat. However, the point at which it loses its structure is incredibly high. This product maintains its chemical stability even when it comes into direct contact with very hot items or exposed flames. This makes it a top choice for several industries that deal with heat tools or electronic components that produce consistently high levels of heat energy.

Applications

Ultem film has many industrial uses. It can also serve a large number of important B2B plastics applications. For example, it is often used by machining companies, military suppliers, science and research firms, and even aviation and aerospace production businesses. Many of these fields require durable materials that can maintain their shape and structure when exposed to impact, sharp objects, or chemical solvents. And almost all of them require heat-resistant materials to maintain safety. Here are a few more specific use cases where Ultem film tends to stand out above other plastic options:

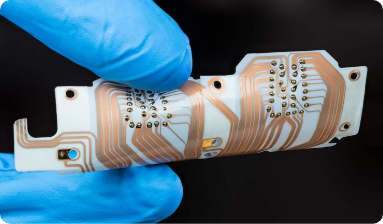

Ultem film is incredibly popular within the electronics industry due to its ability to retain its structure when exposed to heat energy. More specifically, it is often used in the production of flexible circuit boards in printed electronics. It’s strong enough to keep electrical components in proper alignment but thin and flexible enough to work in small devices. The heat resistance of Ultem film even allows it to work as electrical insulation around wiring and other components that produce heat.

Since Ultem film can easily be converted to very custom specifications, it is often used as lining and containers in industrial settings. For example, it may be formed into pouches, compartments, or pockets to house various supplies or used materials. It can even house hot tools or items that have been exposed to chemicals. These qualities make it ideal for interior compartments within aerospace or military applications, which often require fire and heat-resistant materials that comply with industry regulations.

What to Look for in an Ultem Film Supplier

When selecting any plastic film for industrial or B2B applications, it’s important to find a supplier with an extensive inventory and access to products from industry-leading manufacturers. Like all plastic films, Ultem can come in an array of grades and be cut to the specific size needs of your application.

In addition, it helps to work with a provider that has a presence in your local community and one that frequently works with your specific industry. This can provide your business with helpful insights and guide you toward the best possible material and value-added services for each project.

PolymerFilms offers all of these attributes and more. We serve a huge number of commercial and industrial markets. So our team has the knowledge and experience necessary to ensure you can maximize your investment in various plastic film products. We also offer film conversion and cutting services to provide the exact dimensions needed for your projects quickly. Even in a challenging market, our local facilities spread throughout North America are stocked with inventory and able to process orders quickly, giving you a competitive advantage in your industry. Whether you’re looking for Ultem film or any other high-performance plastic film materials, visit our website to find your local facility and reach out for a quote to get started.

Recent Posts