Kelvinite™ FRPP is a high-performance material that stands out for its exceptional strength, impact resistance, and eco-friendly, halogen-free fire-retardant properties. It’s a top choice across industries such as electric vehicles, power insulation, consumer electronics, and medical devices.

Our experts at PolymerFilms have years of hands-on experience with Kelvinite™ FRPP. As we’ve worked through these projects, we’ve organized answers to some of the more frequent questions about Kelvinite FRPP in hopes to help you make the most informed decision about your flame-retardant needs. Explore them below and discover why Kelvinite™ FRPP is the ideal solution for your project.

Q1: What is Kelvinite™ FRPP?

Kelvinite™ FRPP is a halogen-free, flame-retardant polypropylene plastic film designed to meet strict safety and environmental standards across various industries. This material is most known for its great thermal stability and durability. Unlike traditional fire-retardant materials, Kelvinite™ is safer for both users and the environment because it’s halogen-free.

Halogens are a group of very reactive elements that can release toxic gases when exposed to heat or combustion. These toxic gases can cause respiratory problems, contribute to environmental pollution, and even damage the ozone layer. By choosing a halogen-free solution like Kelvinite™ FRPP, you’re prioritizing safety and sustainability without sacrificing performance.

Q2: What Makes Kelvinite™ Different From Traditional Fire-Retardant Films?

Kelvinite™ FRPP is unique in three ways:

- Halogen-Free Formula

Most fire-retardant films contain halogens that put out highly toxic gases upon combustion. Kelvinite™ eliminates all such risks with its formula entirely. - Improved Performance

Kelvinite™ has superior mechanical strength and long life compared to many traditional materials, which in turn makes it the most reliable choice for any application. - Environmental Sustainability

The lack of a halogen formulation in Kelvinite™ reduces undesirable byproducts related to its eventual waste or recycling process, in turn, moving toward a greener, cleaner environment.

Q3: Which Industries Benefit Most from Kelvinite™?

- Aerospace: Used for electrical insulation.

- Electronics: It acts as a barrier to protect circuit boards, batteries, and other components.

- Construction: Ideal for wall linings and insulation materials.

- Automotive: Makes for great electrical insulation of under-the-hood components Packaging: Used to pack high-value or hazardous goods with its flame-retardant properties.

- Medical: It serves as a thermal solution for various equipment.

Q4: How Does Kelvinite™ Perform Under Fire Conditions?

Kelvinite™ FRPP is purpose-built for fire safety. Self-extinguishing properties reduce flame spread, while as a halogen-free material, it minimizes the release of smoke and toxic fumes. Features such as these make the material highly suitable for applications where fire safety is a priority.

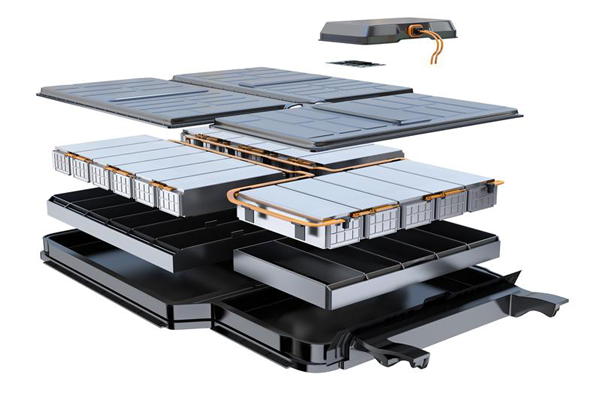

Let’s consider the automotive industry, for example, where Kelvinite™ helps with resistance to tracking under wet and contaminated conditions for critical electrical applications. Some application examples include:

- Battery Cell Separator

- Battery pack cover

- Battery pack case insulation

- Cell cover

- Module Case Insulation

- On-board charger insulation

- Charging station insulation

- Busbar insulation

- BMS insulation

Q5: Is Kelvinite™ Compliant with Regulatory Standards?

Yes. Kelvinite™ FRPP meets or exceeds international safety and environmental regulations, including:

- RoHS Compliance (Restriction of Hazardous Substances) for electronics.

- REACH Standards (Registration, Evaluation, Authorization, and Restriction of Chemicals) for chemical safety.

- Various ISO fire safety certifications, depending on specific applications.

At PolymerFilms, we make sure that our Kelvinite™ products align with the latest industry requirements.

Q6: Can Kelvinite™ Be Customized for Specific Applications?

Absolutely. Kelvinite™ FRPP is available in a variety of thicknesses, widths, and finishes. Here at PolymerFilms, we work hand-in-hand with customers when it comes to particular custom applications, including single and specialized project requirements.

Why Choose PolymerFilms for Kelvinite™ FRPP?

With decades of experience, PolymerFilms is more than a distributor—we’re a partner in your project’s success. Our team has worked extensively with Kelvinite™ FRPP and can provide:

- Expert advice on application-specific requirements.

- Custom cutting services to match your specifications.

- Technical support to maximize the potential of every project.

Read more on our product page about Kelvinite™ FRPP to review all the possibilities/options for your next project. Partner with a distributor who stands behind their products and solutions by contacting our team of experts today.

Recent Posts